High-density polyethylene (HDPE) is used to make bottles for fruit juice, milk, water, kitchen cleansing products and even dust bins including recycling bins. It has been used in recent years for garden furniture and recycling bin as it resists the weather and can be cleaned very easily.

High Density Polyethylene (HDPE) is the largest of the three polyethylene (PE) by volume of consumption. It has a very linear structure with only few short side branches leading to a higher density range as well as a more crystalline structure. These properties give HDPE its higher strength compared to the other PEs. Allowing a wider range of uses.

A major outlet for HDPE is in blow-moulding applications such as bottles for milk and other non-carbonated drinks, drum, fuel tanks for automobiles, toys and household goods. Because HDPE has good chemical resistance, it is used for packaging many household and industrial chemicals such as detergents, bleach and acids.

HDPE can be injection moulded into articles including crates, pallets, packaging containers and caps, household goods and toys. It can be extruded into pipes for water, natural gas and irrigation, corrugated pipe for drains and sewers, and conduit for electrical and telecommunication cables.

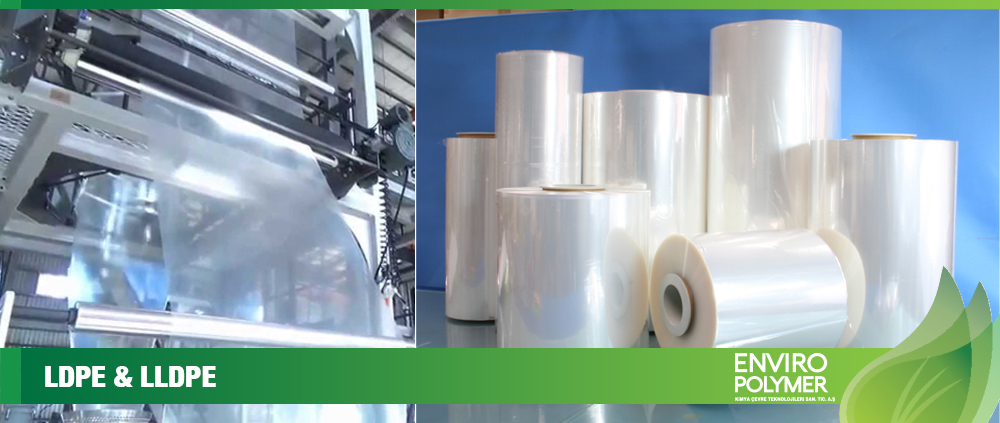

Low-Density Polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. LDPE is the low density version of PE. This has less hardness, stiffness and strength compared to HDPE, but better ductility. This chemical is used for packaging like foils, trays and plastic bags both for food and non-food purposes also it is as protective coating on paper, textiles and other plastics.

Low density Polyethylene (LDPE) is used mainly in film application for both packaging and non-packaging applications. Other markets include extrusion coating, sheathing in cables and injection moulding applications.

LDPE is the oldest and most mature of the polyethylenes (PE). It is characterised by its short and long chain branching which gives it good clarity and processability although it does not have the strength properties of the other PEs.

Non-food packaging applications embrace industrial liners, stretch- and shrink-wrap, garment bags and merchant bags.

Non-packaging film applications cover carry-out bags, waste bin liners and garbage bags, industrial sheeting, and construction and agricultural films.